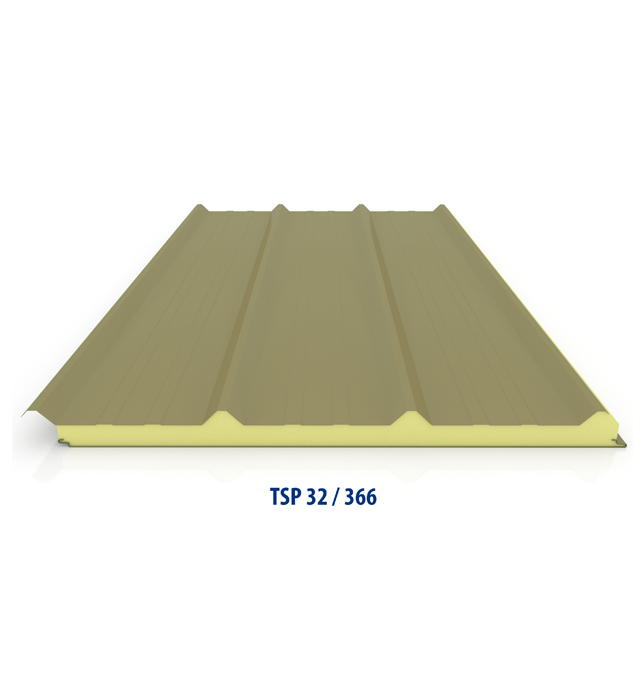

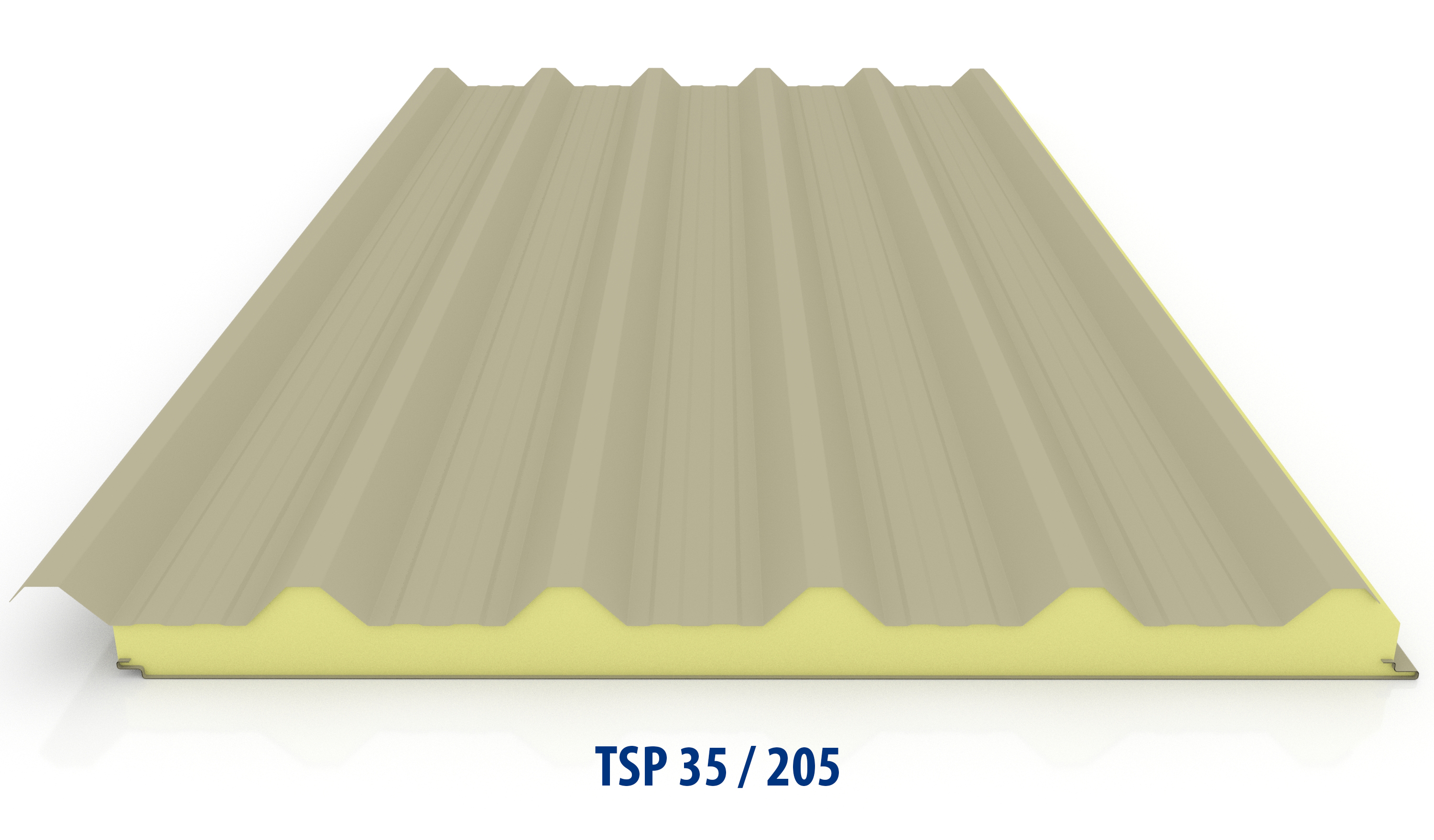

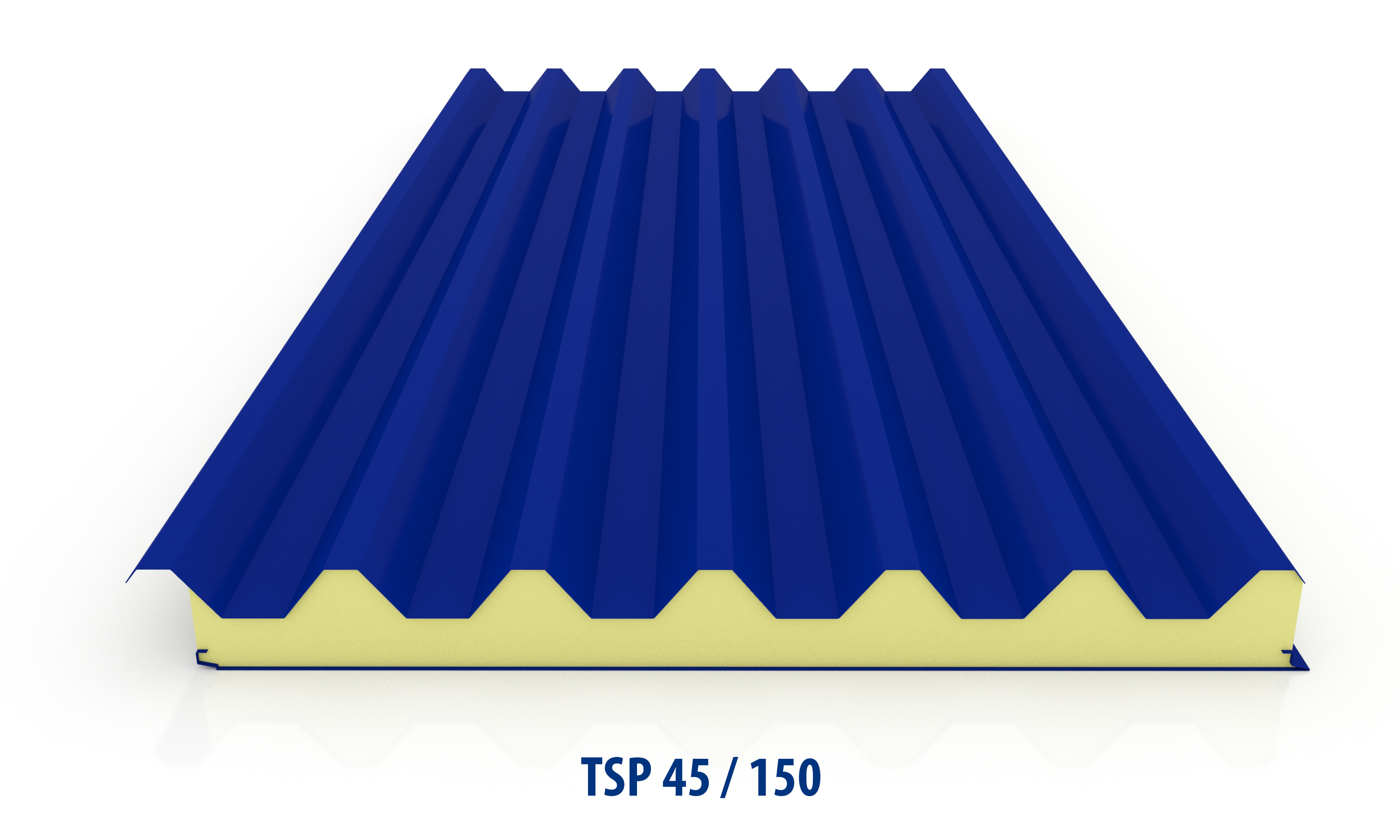

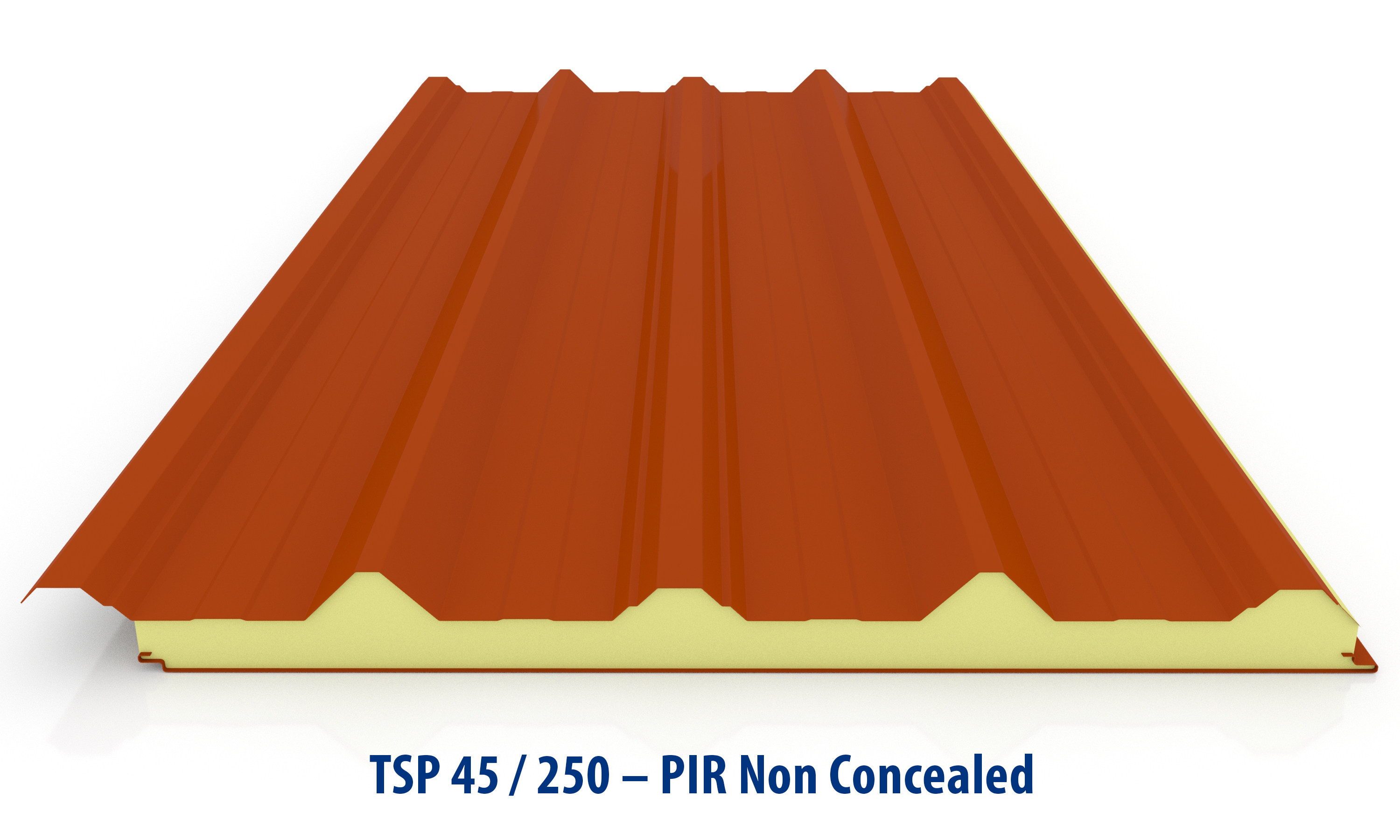

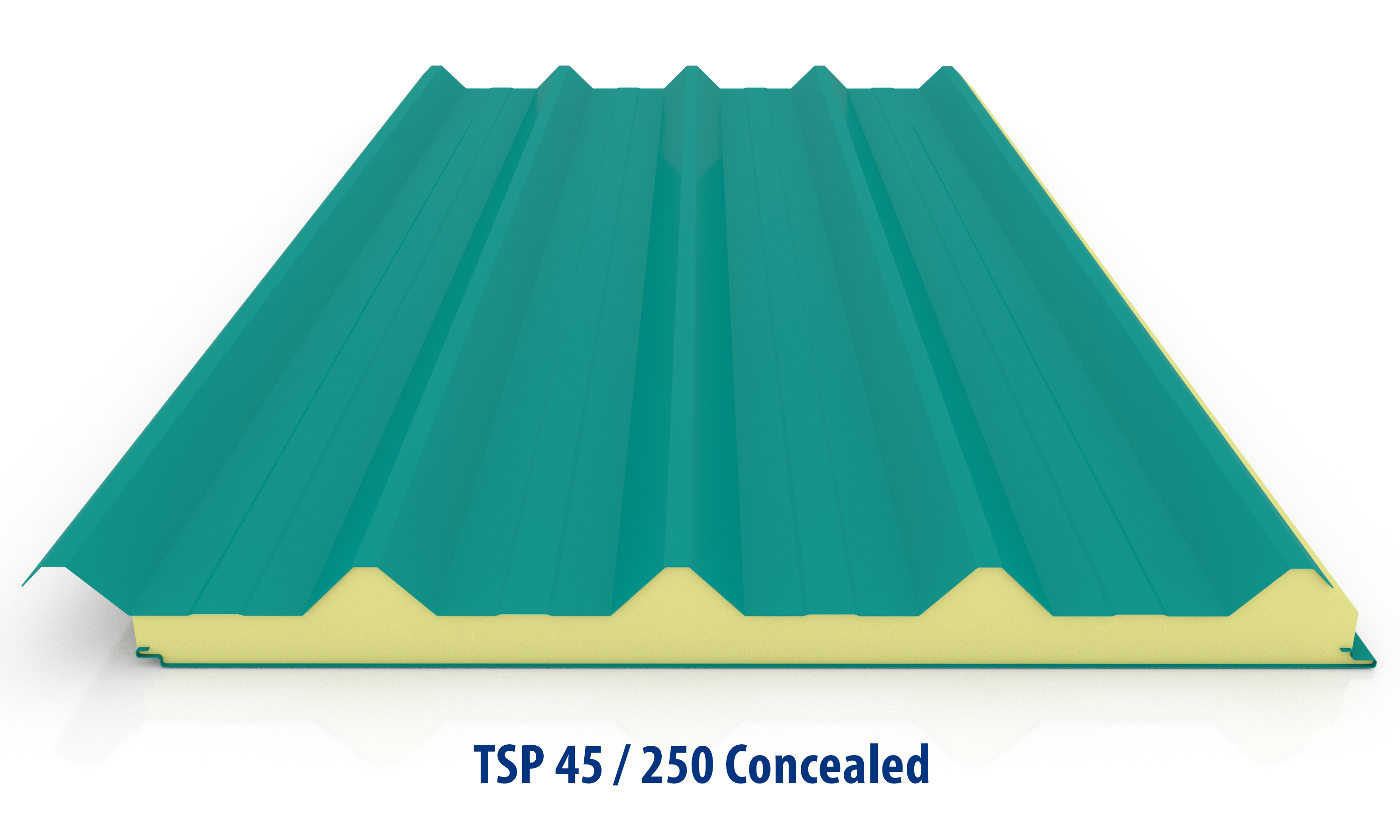

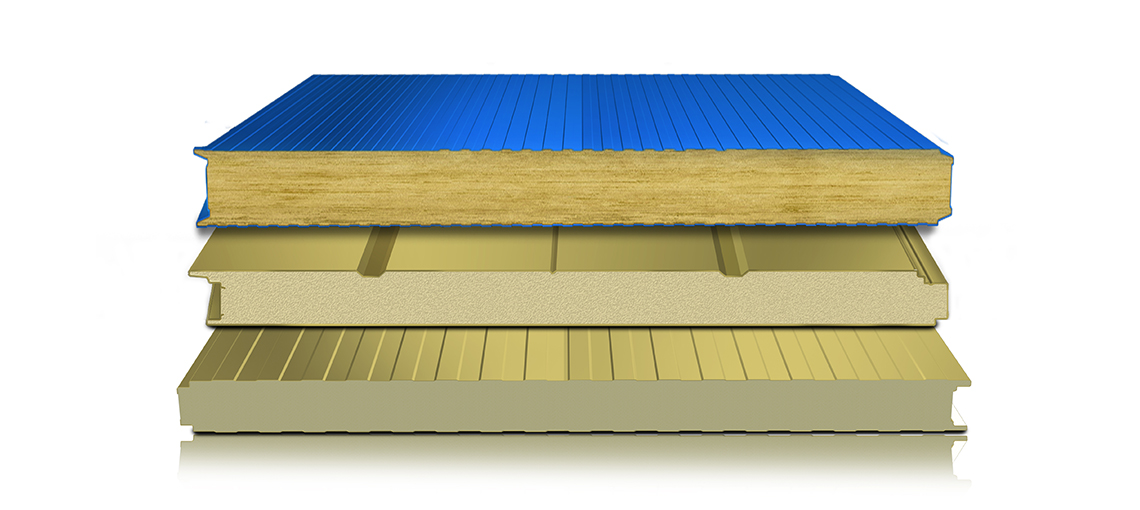

Corrugated Insulated Panels

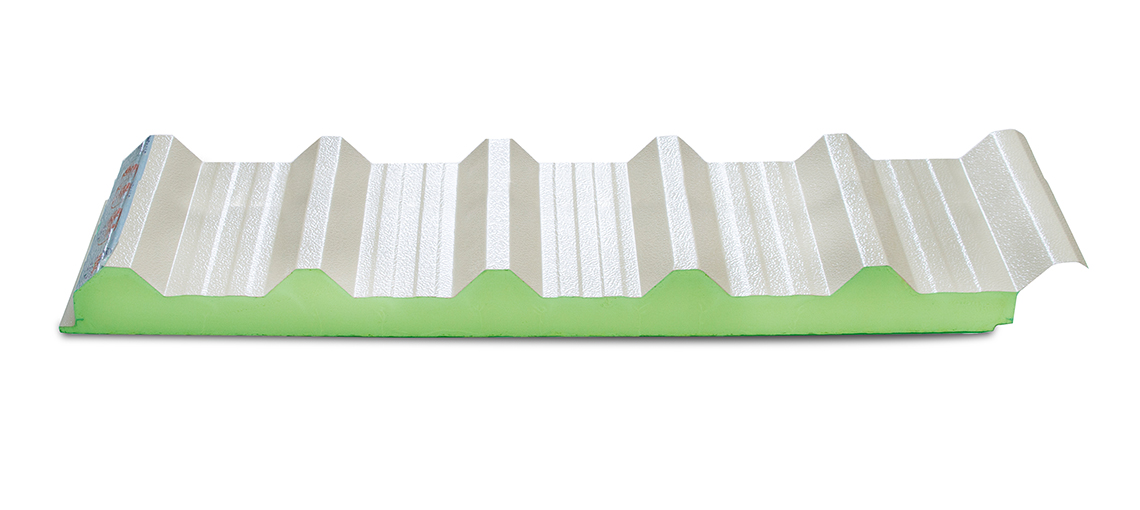

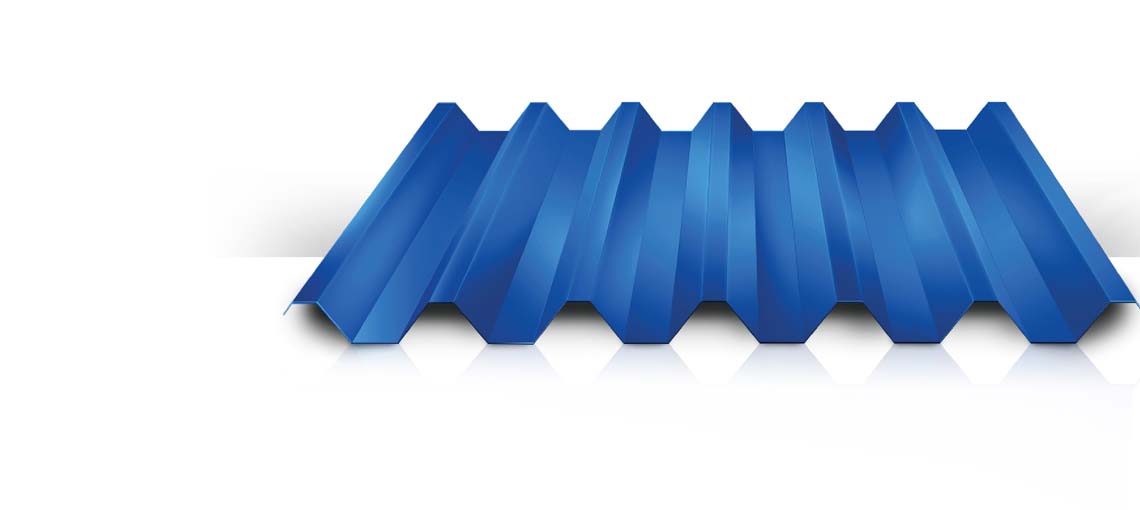

Corrugated insulated sandwich panels feature a unique sandwich construction with Rockwool or Polyisocyanurate (PIR) as the core material between two rigid metal facings. Designed to be used for horizontal, pitched roofs as well as vertical wall installations for industrial and civil structures the corrugated / trapezoidal sandwich panels are light in weight, have fire resistance properties, provide excellent thermal resistance and are available in different profiles.

Standard Colors

| TSR Avg. | SRI Avg. | |

CI24-0048 | RAL9001 | 72.1% | 88% |

CI24-0049 | RAL9016 | 75.1% | 93% |

CI24-0056 | RAL9010 | 73.3% | 90% |

CI24-0057 | RAL9003 | 74.7% | 92% |

CI24-0058 | RAL9002 | 66.9% | 81% |

CI24-0054 | RAL9015 | 69.1% | 84% |

CI24-0055 | RAL9014 | 62.7% | 76% |

CI24-0059 | RAL1001 | 54.6% | 65% |

Calculation Parameters:

Emissivity rating: 0.9

Average is calculated at 3- different wind speed factors (0-2 m/s; 2-6 m/s; 6-10 m/s)

Features

- Brings Everlasting Life To Buildings

- Long Decorative Life Coupled with Low Maintenance

- Color Coating as Per Ral 840 - Hr & Ral 841 - Gl

- Wide Variety of Color Choice is available subject to external lead time

- Metallic Colors & Harsh Weather Proof Coatings are also available.

*Note: Additional Colors are available upon request.

| TECHNICAL DATA SHEET | |

| RIGID POLYISOCYNURATE (PIR) FOAM FOR ROOF PANELS | |

| PHYSICAL AND MECHANICAL PROPERTIES | |

| Insulation Core | Rigid Cellular Certified "Fire-Resitant" Polyisocyanurate (PIR) foam |

| Closed-Cell Content | > 93% as per DIN ISO 4590 |

| Thermal Conductivity (Lambda Value) | 0.025 W/m.K |

| U - Value | 0.288 W/m2 K (Considering 45/250 Profile) |

| Trapezoid Corrugated Panels for Roof | 75mm thick Roof 45/250 Composite PIR Panel |

| Overall Density | 40 ± 3 kg/m3 as per BS EN 1602 |

| Blowing Agent | Environment Friendly cyclo-Pentane gas (Zero ODP) |

| Compression Strength | 0.140 Mpa as per BS EN 826 |

| Tensile Strength | 0.140 Mpa |

| Shear Strength | 0.120 Mpa as per ASTM C 273 |

| Humid Age Exposure (In TSSC record the test is named as Dimensional Stability Test conducted at 90% relative humidity and 70 +/- 2 deg C. | Length and Width < 2% and Thickness < 6 % as per BS EN 1604 |

| Heat Exposure (In TSSC record the test is named as Dimensional Stability Test conducted at 90% relative humidity and 70 +/- 2 deg C. | Length and Width < 2% and Thickness < 6 % as per BS EN 1604 |

| Dimensional Stability (48 Hrs.) | As per BS EN 1604-1 |

| Deg -25 | Complies |

| Deg +36 & 00 % RH | Complies |

| Deg +100 | Complies |

| Average Water Absorption (2 Hrs.) by Vol ( %) | < 1 % ( tested as per ASTM C 209 ) |

| DIMENSIONAL TOLERANCE | |

| Thickness (mm) | T ≤ 100 mm ± 2 mm, T > 100 mm ± 2% |

| Width (mm) | ± 2 mm |

| Length (mm) | L ≤ 3000 ± 5 mm, L > 3000 ± 10 mm |

| TEST CERTIFICATES FOR FIRE-PROPERTIES | |

| FM 4471 & FM 4881 | Passed .Class 1 Roof requirement FM 4471 ( System available based on special project requirements) |

| ASTM D 1929 Flammability Testing | Passed.Self Ignition Temperature of PIR Foam greater than 343 deg C . |

| Dubai Central Laboratory (DCL) | Passed (EN 13165,ISO 11925-2 Single Flame test ) |

| ASTM E84 | Passed ( Class A) with less Flame spread and less Smoke development |