Introduction

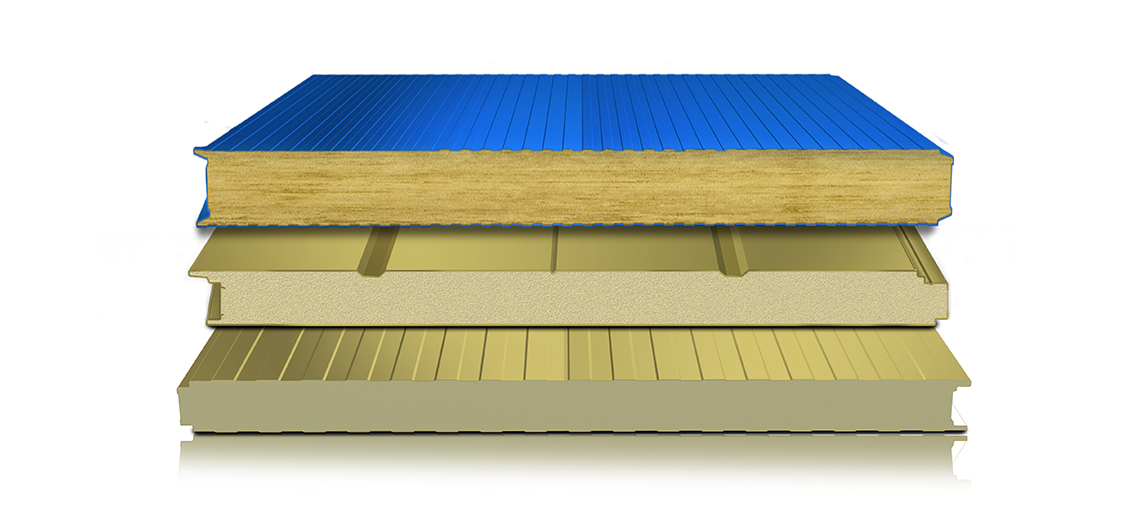

Sandwich PUF Panels are being used more frequently in the realm of modern building and cold storage solutions. These polyurethane foam panels, also known as PUF panels or Polyurethane Foam Panels, provide a flexible and effective solution for a variety of applications, notably in cold storage facilities. TSSC is a well-known brand in the market that offers premium Sandwich PUF Panels. The benefits of employing a Sandwich PUF panel for cold storage for your construction and cold storage needs will be discussed in this blog.

Outstanding Thermal Insulation

When it comes to the PUF panel for cold storage, keeping the temperature steady and low is crucial to ensuring the quality and security of the kept items. Due to its remarkable thermal insulation qualities, sandwich PUF panels thrive in this area. These panels have a polyurethane foam core, which is well known for its excellent thermal performance.

Sandwich PUF panels provide superior thermal insulation and low thermal conductivity which helps to maintain the temperature within the cold storage facility. This not only maintains the quality of the products but also uses less energy over time, saving money.

Power Savings

The possibility for large energy savings is one of the most important benefits of adopting sandwich PUF panels for cold storage. The PUF panels from TSSC have remarkable thermal resistance and are designed to minimize thermal bridging. The PUF panels have continuous insulation throughout the wall surface, reducing heat loss or gain through these bridges and improving energy efficiency. For companies that run cold storage facilities, this energy-efficient insulation can significantly reduce energy consumption and result in long-term cost reductions that are considerable.

Long Lasting and Resilient

Construction of cold storage facilities must consider durability because of the fluctuations in temperature and the continual movement of items. Sandwich PUF Panels from TSSC are renowned for their durable design and endurance. They are made to endure the demands of cold storage conditions, guaranteeing that your facility will last for many years.

Installation simplicity

Sandwich PUF Panels’ simplicity of installation is another benefit. The panels are manufactured in a controlled environment setting and then brought to the job site. This drastically cuts down on-site labor and construction time, lowers costs and expedites project completion. PUF panels from TSSC are an efficient option for building projects including cold storage since they are designed for simple installation. The slip joint & camlock jointing system facilitates assembly and dismantling quickly, therefore, fewer workers or non-HVAC trained personnel are required. The jointing system also gives an aesthetic sense by hiding the joints. Steps to be followed in the installation of PUF panels is to determine the size of the cold room, calculate the surface area of the cold room, determine the thickness of the PUF panels required for the installation, and place the order PUF panels from TSSC.

Choices for Customization

Every cold storage facility is different, with particular needs and spatial limitations. Sandwich panels from TSSC may be customized in a variety of ways to match the precise needs of your project. Customization enables you to adapt the panels to the unique requirements of your cold storage facility, regardless of whether you need panels with particular dimensions, distinct thicknesses, or alternative finishes.

Resistance to Moisture and Corrosion

To stop mold and germs from growing, PUF panels for cold storage facilities must maintain a dry, clean atmosphere. Sandwich PUF Panels from TSSC are created to be moisture-resistant, guaranteeing that they maintain outstanding condition even in areas with high relative humidity levels. These panels are also corrosion-resistant, which makes them perfect for cold storage facilities with variable humidity and temperature.

Fire Protection

Any building project must prioritize safety. Sandwich PUF Panels from TSSC are created with fire safety in mind. They have good fire-retardant qualities that, in emergencies, can aid in containing and reducing the spread of fire. In cold storage facilities where the storage of delicate commodities is practiced, this additional degree of security is crucial.

Environmentally responsible

Construction and building materials are increasingly focusing on sustainability. Sandwich PUF panel for cold storage are eco-friendly since they have less influence on the environment. They utilize less energy, which lowers the greenhouse gas emissions brought on by heating and cooling. These panels may be recycled, which helps the building sector become more environmentally friendly.

Cost-Saving Approach

Sandwich PUF Panels’ long-term cost-effectiveness becomes clear. Over the course of your cold storage facility’s life, lower operating expenses will result from energy savings, longevity, and minimal maintenance requirements. The dedication to quality guarantees that your investment in PUF panels for cold storage will pay off in terms of effectiveness and cost savings.

Applications for Cold Storage with Flexibility

Sandwich PUF Panels provide flexibility in applications for cold storage. They may be used for a variety of things, such as blast freezers, walk-in coolers, refrigerated warehouses, and refrigerated trucks. These panels may be tailored to the precise temperature needs of your application, whether you are storing perishable commodities, frozen goods, or medications.

This adaptability includes both new PUF cold storage facility development and refurbishment and extension of existing ones. PUF panels are flexible, making them a good option for a variety of cold storage solutions.

Conclusion

It makes sense to utilize Sandwich PUF Panels from the TSSC when building PUF panels for cold storage facilities. In addition to effective thermal insulation, these panels also save energy and are simple to install. They offer moisture and corrosion resistance and can be tailored to your project’s exact needs. Sandwich PUF panels are also cost-effective in the long run and ecologically benign. Sandwich PUF panels are a great choice for cold storage facilities needing dependable and effective insulation, and they are supported by the TSSC’s reputation for providing high-quality building materials.