The increasing demand for housing is making way for the escalation of prefab buildings in Oman. Modular buildings are prefabricated construction that has recurring sections called modules. Prefab construction is assembling various components at a building site in the form of a module. Prefab construction is common in the Qatar industry. Commercial buildings utilize prefabricated walls, ceiling panels, flooring systems and plasterboards. Prefab buildings in Oman are manufactured in large quantities, including doors, windows, stairs, rooms and roof trusses. Prefabrication is a faster and more sustainable process in the construction industry. A building can be built faster by implementing prefabrication. The precast concrete units are solidified and cast before being used in building and construction. Prefab construction forms less waste material and can be recycled.

Knowing the prefabrication advantages

Prefabrication is different from traditional construction because the former is suitable for projects with higher redundancy. Have you experienced delays in construction due to a lack of workforce? This is a very common scenario in traditional construction because the demand for labor is huge which sometimes cannot be fulfilled. They are working for multiple sites simultaneously for bigger earnings and finishing off projects. The weather plays a villainous role by showing extremities that could delay traditional construction. Buildings erected following the traditional construction method take months to even more than a year to complete. Prefab buildings can be built in just a couple of months. Prefab buildings in Oman involve lesser expense compared to site-built homes. The factories where the prefab components are manufactured are usually set in cheaper areas like the interior and suburbs. Some of the other advantages of prefabrication include energy efficiency, minimal waste, not much inspection, speedy construction, sustainability, protection and quality.

Knowing about TSSC Group and the engineers

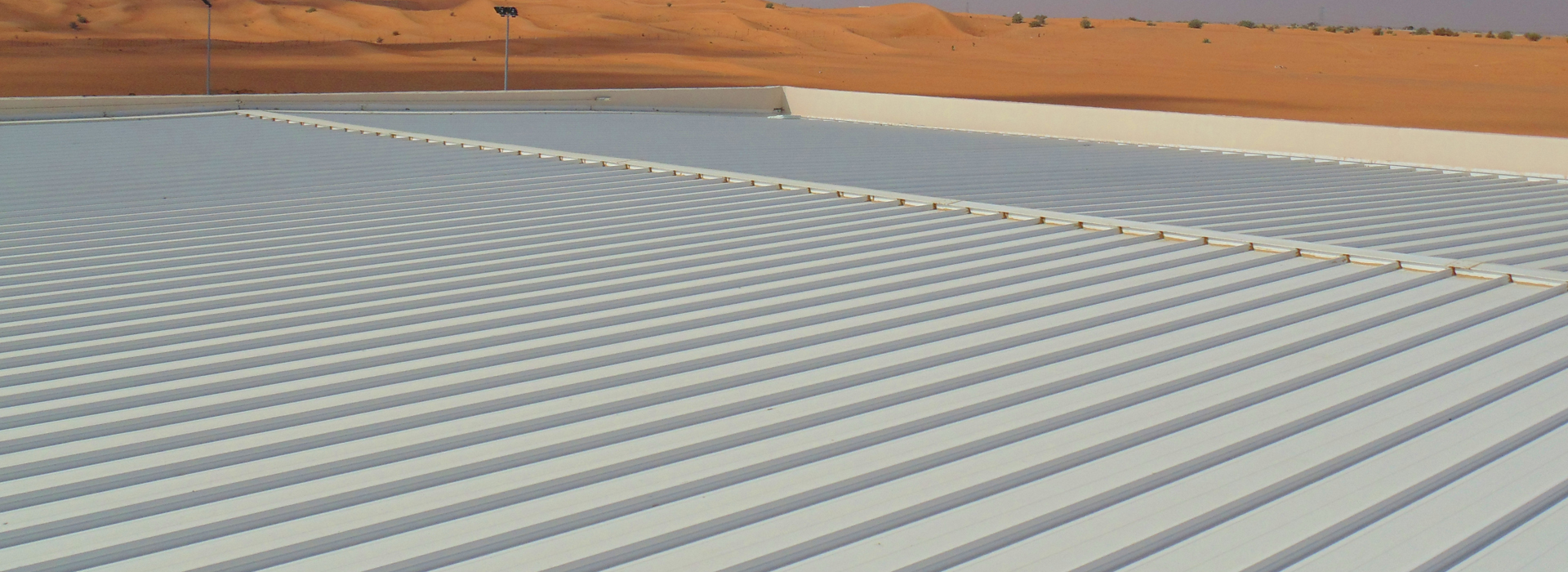

TSSC Group is one of the leading prefab building manufacturers in Oman. We have a huge number of clients from various industries. Our engineers design insulated solutions for roofing and cladding. TSSC Group is an ISO 9001 company with more than 50 years of experience in offering concrete solutions to clients. We offer customized prefab buildings in Oman keeping in mind your needs and considering the budget factor. TSSC Group has state-of-the-art manufacturing units and has the largest production capacity in the entire country. TSSC building and construction products meet international standards and are tested for durability and functionality. We have a team of experts who design innovative solutions.

Final words

Do you know that prefabrication reduces onsite work? Prefabrication is an upscaling trend that is popular in the modern building sector. Prefabrication minimizes project deadlines by almost 50% and reduces the construction cost by a minimum of 20%. The building and construction industry is advancing towards stabilization. Please book a consultation with our experts for a customized solution. We have a team of talented experts who manage your project from the planning phase to assembling, execution and final delivery. TSSC Group is continuously working towards designing environment-friendly solutions.

Please discuss your modular project with us for an effective solution—request a no-obligation quote.